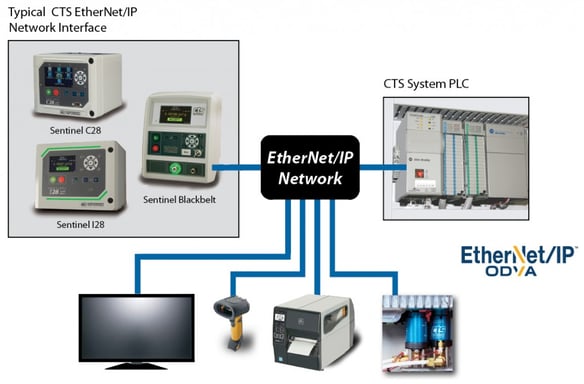

To meet customer demand and improve the performance and functionality of our leak test instruments, Cincinnati Test Systems (CTS) provides advanced EtherNet/IP communications software. As the standard leak test communication option for our

Sentinel I28,

Sentinel C28,

Sentinel Blackbelt, and

Sentinel Blackbelt Pro devices, EtherNet/IP provides greater I/O capacity via standardized CIP programming.

While all our leak testing instruments feature a number of I/O connections, there are times when the available inputs and outputs are not enough to control and monitor all the necessary processes. With EtherNet/IP, your CTS device will gain 10 pre-configured inputs, nine defined outputs, and 16 user-definable inputs and outputs.

Built for simple plug-and-play functionality, EtherNet/IP connects your CTS instrument to the PLC via a single cable utilizing the RJ45 network communication port. Hardware based I/O systems require that devices be physically installed, including hardwiring of individual ports. EtherNet/IP is a software-only package, making installation fast and easy and eliminating the need for time-consuming rewiring. All it takes is a few minutes to program and connect devices through EtherNet/IP. Through the connection, users can carry out Sentinel instrument I/O functions, machine functions, and communications from the PLC.

EtherNet/IP also relays real-time test results and data, machine test errors, and other vital data. Test information can be displayed, recorded, and stored for future use. Features & Benefits

High-Efficiency Control, Configuration & Messaging of EtherNet /IP

Conformance tested by ODVA to ensure flawless operation and verified data exchange that works the first time, every time, EtherNet/IP provides a unified communication network. It allows you to efficiently control, configure, and send messages between CTS leak test instruments and Allen-Bradley ControlLogix® or CompactLogic™ PLCs (programmable logic controllers).While all our leak testing instruments feature a number of I/O connections, there are times when the available inputs and outputs are not enough to control and monitor all the necessary processes. With EtherNet/IP, your CTS device will gain 10 pre-configured inputs, nine defined outputs, and 16 user-definable inputs and outputs.

Built for simple plug-and-play functionality, EtherNet/IP connects your CTS instrument to the PLC via a single cable utilizing the RJ45 network communication port. Hardware based I/O systems require that devices be physically installed, including hardwiring of individual ports. EtherNet/IP is a software-only package, making installation fast and easy and eliminating the need for time-consuming rewiring. All it takes is a few minutes to program and connect devices through EtherNet/IP. Through the connection, users can carry out Sentinel instrument I/O functions, machine functions, and communications from the PLC.

EtherNet/IP also relays real-time test results and data, machine test errors, and other vital data. Test information can be displayed, recorded, and stored for future use. Features & Benefits

- 10 preconfigured inputs, 9 defined outputs

- 16 additional programmable I/Os

- Easy, one-cable RJ45 interface connection

- Fully software-based for fast installation & connection

- Control & monitor I/O functions via PLC

- Real-time test messaging of pass/fail, errors & system I/O status directly to PLC or remote terminal

- Active program selection

- Send & receive ASCII barcode information along with test results (for Blackbelt and I28 devices)

- Provides test summaries including data & query of complete data string

- Latch feature for multi-device communications

- Standard communication option for CTS devices—no extra charge for installation, licensing, etc.