Accurate, reliable leak test solutions to meet the stringent requirements of data center cooling systems

Data Center Cooling Leak Testing

Data centers are the backbone of the digital world, housing the servers and networking equipment that power everything from cloud computing to online banking.

These systems generate massive amounts of heat, making efficient and reliable cooling essential to maintain performance and prevent hardware failures. Leak testing these parts, components, and assemblies is a crucial part of the manufacturing process to ensure cooling systems operate effectively in the field.

Undetected leaks in liquid chilled systems and refrigerated systems can lead to equipment overheating, increased energy consumption, and costly downtime. CTS’ leak test solutions are designed to ensure the reliability and quality of data center cooling systems.

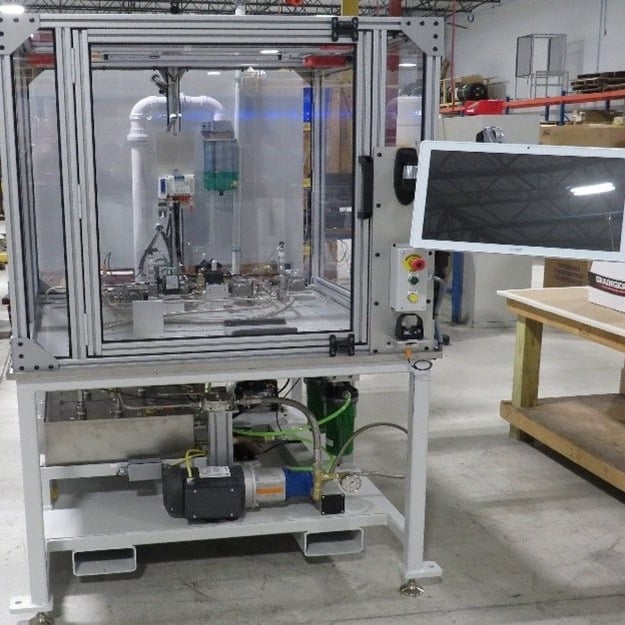

Dependable, flexible leak test systems for manufacturers, built for stringent and ever-evolving industries

The data center cooling industry is ever-changing and evolving with the development of technologies. This makes flexible solutions paramount to the efficiency and future needs of your manufacturing line.

CTS leak test solutions can be customized to nearly any application, including heat exchanger systems, air handling units and cooling distribution units, liquid bath immersion systems, refrigerant systems, cooling plates, piping systems, valves, pumps, and more.

Common data cooling system components requiring leak testing include:

- Coils

- Heat Exchangers

- Refrigeration Valves

- Expansion Valves

- Water Valves

- Flexible Hoses and Copper / Aluminum Assemblies

- TXV Valves

- Copper Manifolds and Tube Assemblies

- Cold Plates

- Compressors

- Capacitors

- Switch Gear

- Controls

CTS offers a wide range of solutions for both liquid leak applications (such as water, water/glycol, mineral oils, dielectric fluids, fluorinated liquids, and other fluids), and gas leak applications (including inert gases, reactive gases, and hazardous materials, including Hydroflourocarbons (HFCs), Hyrdrofluoroolefins (HFOs), propane, and CO2) to meet your requirements.

Leak Test Solutions Built for Data Cooling Suppliers

To ensure heating, ventilation, air conditioning, cooling and refrigeration systems stabilization and efficiency it is important to perform leak tests during manufacturing and as part of a preventative maintenance program.

COLD PLATE ASSEMBLY

Various methods can be used when leak testing a cold plate assembly, depending on your specifications and throughput goals. Common methods include pressure decay leak testing, accumulation, burst and cycle testing, and more. Systems can be designed with ultimate flexibility to accommodate different part designs on the same test machine.

CIRCUITS AND COILS

Leak testing circuits and coils can include accumulation leak testing (testing for leaks from the refrigeration circuit to the water coolant circuit) & sniff leak location (to locate specific leaks in the refrigerant circuit). Using CTS’ TracerMate II, the test is initiated, controlling evacuation and test pressure filling of the refrigerant system, then measuring accumulation of tracer gas in the water circuit.

COOLING ASSEMBLY

The cooling assembly is a large assembly requiring a Proof Test. The leak test system charges a complete cooling system to conduct the test. CTS’ TracerMate II instrument is used to pressurize the assembly to the range of 0 – 1000 psig. The system includes high pressure ball valves and an air booster with enough tank volume to manage supplying air into the part for reduced cycle time. Leak testing may follow a proof test to validate that the system was not over stressed causing a leak from the proof test.

HELIUM RECLAIM SYSTEMS

For leak test applications utilizing helium, a helium reclaim system is often recommended. These systems allow manufacturers to reduce helium costs and dependency on helium suppliers. The system is designed to capture exhausted helium into low pressure recovery tanks after test. These systems may also mix recovered helium with higher concentration helium to bring it up to the correct test mix percentage. The helium is then supplied back to the test stations from the high-pressure tanks.

Talk to a Leak Test Expert

We offer solutions for nearly any application! Talk to our leak test specialists about your application.

WEBINAR - Precision Testing for Data Center Cooling Systems

Learn the latest leak testing best practices, technologies, and industry standards to enhance system reliability as it relates to data center cooling components and systems.

Wide Selection of Leak Test Technologies

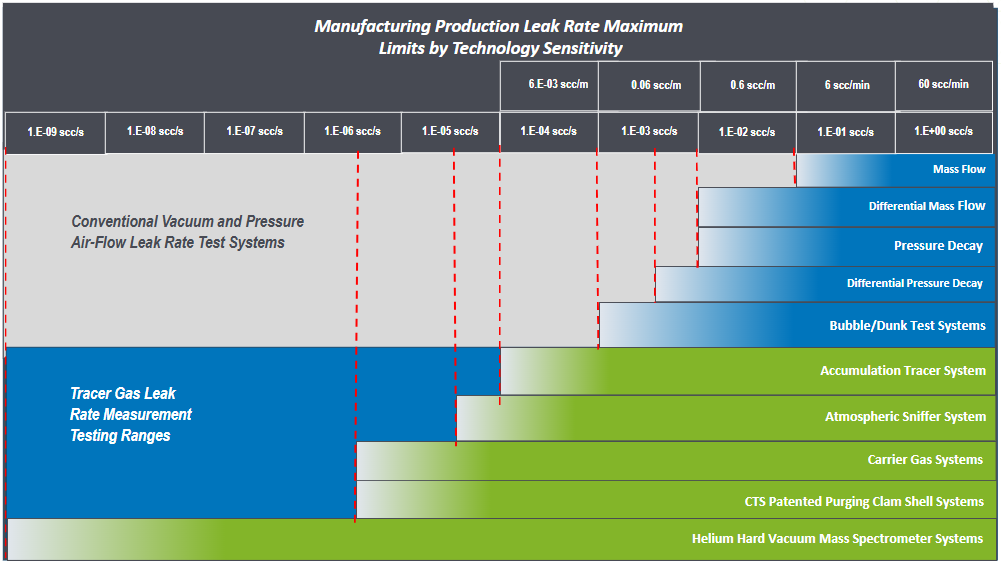

The ideal leak method and technology for your applications will depend on a variety of factors, including part/component use in the field, leak material, part size and design, throughput and cycle time goals, and more. CTS will work with you to understand your application and design a system best suited to your requirements.

Our systems offer a variety of air leak testing options, including pressure decay, differential pressure decay, mass flow, and more. When pressure testing technologies due not fit the application, tracer gas (helium, forming gas, etc.) technologies are used, such as tracer gas accumulation, nitrogen purge technology, hard vacuum mass spectrometry, sniff/leak location, and more.

CTS helps manufacturers solve leak testing challenges and stay ahead in an evolving market

Data center cooling manufacturers and suppliers face many challenges, including:

- Stringent manufacturing product quality requirements

- Balancing production costs and the push for efficiency while producing the highest quality products

- Frequent leak testing scope changes due to new cooling applications and the developing needs of the market

- Difficulties in defining acceptable leak rates and methods with new data center cooling technologies

Talk to a Leak Test Expert

With over 40 years’ experience, CTS specializes in helping manufacturers design and refine their leak testing processes to deliver accurate and consistent results. Our experts can identify potential issues that may affect leak test accuracy and repeatability, and offer recommendations to optimize performance.

Contact us today to speak with a leak testing specialist!