[Case Study] How the Right Leak Test Seal Can Save You $30K Per Month

Connectors and seals play a critical role in the accuracy and reliability of a leak test. Even when doing everything else right, having the right leak test machine, optimized leak test limits, custom fixturing, and more, just one poor seal can cause unreliable, inconsistent results. This inconsistency can lead to line downtime, decreased throughput, and hours wasted on root cause analysis and rework.

But don’t fret, CTS is here to help! Along with an expansive offering of standard, high-quality seals and connectors, CTS also offers custom consulting and design-to-build sealing solutions. As the leaders in leak test with over 40 years’ experience, we have extensive experience in ensuring a strong seal, in any situation.

CONSIDERATIONS TO CHOOSE THE RIGHT CONNECTS AND SEALS →

Customer struggling with repeated leak test failures

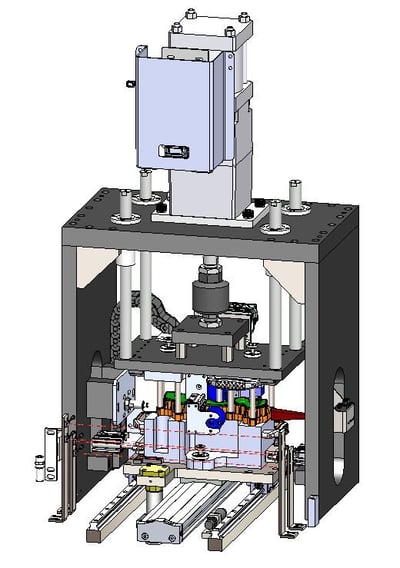

Our team recently solved a problem puzzling a major automotive supplier, they were experiencing repeated leak test failures on a key powertrain component, the orifice valves inside an oil separator assembly, despite the parts passing upstream validation. The manufacturer was facing significant false failures with the leak test at the end of the line, roughly 30-35 parts of 100 PPH were being rejected. This had become costly, resulting in scrap parts, rework costs, line downtime, and lower throughput rates.

CTS engineers were brought in to identify why these false failures were occurring and implement a solution.

Determining the cause of the problem

CTS quickly determined that the problem stemmed from the seal—a very important component in ensuring a repeatable, reliable leak test.

The leak test fixture’s pneumatic seal and seal holder was improperly interacting with the valve component's outer diameter (OD). The seal would come around the OD and would compress or break the teeth on the end of the orifice valve, restricting the movement of an internal check ball. Since the ball couldn't move into position, the leak tests falsely indicated failure.

.jpg?width=400&height=300&name=image%20(20).jpg)

The noteworthy fact here was that this was only happening on some of the assemblies. Since some parts were still operating properly, as designed, during the leak test sealing process, it was evident that there was some variation upstream causing the inconsistency. By investigating the parts causing the false failures, CTS engineers quickly identified the source of the problem: the laser weld process.

The valve had a degree of float prior to the welding process which secured the valve into the orifice. This room for float meant that the valve could be secured at slightly different positions—a very small allowance, but enough to interfere with the current sealing design.

Designing a custom seal solution for a challenging situation

The original leak test seal design had a very tight seal tolerance of ±0.005. While a tight seal is required for a quality leak test, in this case, it was evident that the tolerance would need to account for a greater variance of location for the secured valve, as introduced during the weld process.

The CTS team examined part drawings and tolerances, then redesigned a custom seal holder to accommodate for the potential positional variation in the component’s OD.

This new seal design no longer over-constrained the orifice valve, allowing the internal check ball to move freely and enabling accurate, repeatable test results.

The result? CTS’ custom seal solution saves customer $30K per month

The seal redesign significantly improved test reliability and eliminated false failures, reducing scrap rates and slowdowns and saving the customer an estimated $30,000 per month.

CTS’s deep understanding of sealing, both in custom applications and with standard CTS Connect products, proved critical to solving this problem quickly and effectively, with impressive results for the customer. This solution demonstrated the full flexibility and effectiveness of CTS sealing technology and expertise.

Looking for a reliable seal? Check out CTS Connect standard and custom seals →