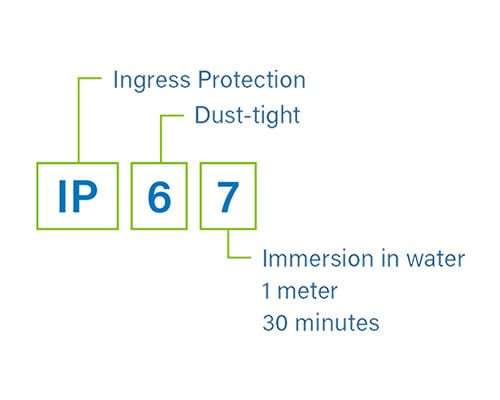

How Does IP67 Leak Testing Work?

To test to IP67 or other IPXX ratings, we start by looking at the part—how it is designed, its materials and how it’s assembled. From there we establish the appropriate leak rate based upon the IP rating targeted, and these factors lead to the selection of the appropriate leak test method. An automated, dry, non-destructive leak test is recommended for better accuracy and repeatability, while also enabling continuous improvement.

What is the Process for Sealed Device Leak Testing?

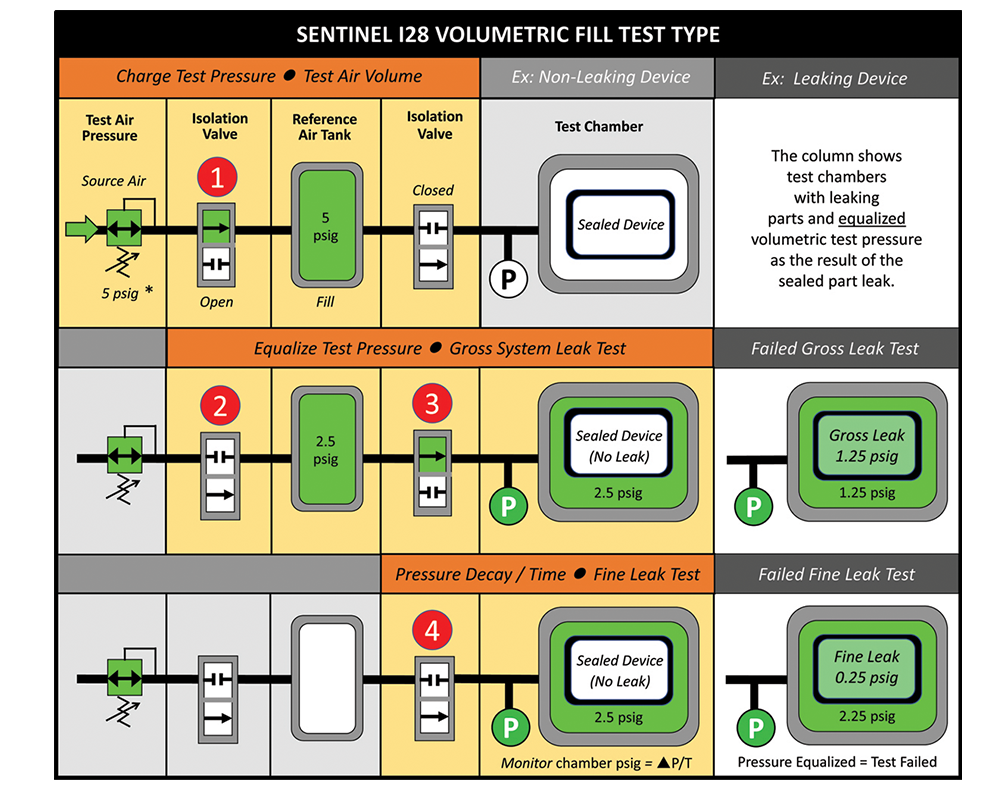

To meet an IP67 rating, sealed devices must resist dust exposure and withstand submersion in up to 40 inches of water for 30 minutes. Sealed devices cannot be tested using conventional pressure or vacuum decay testing because they are sealed and do not have ports to apply pressure or vacuum to test for leaks. At CTS we often use a volumetric fill test process, which is a form of pressure decay testing.

To test a sealed device the part is placed inside a sealed chamber and the leak test is conducted on the air or space inside the chamber surrounding the outside of the part and tested for air being forced inside the part or for air to escape the part. The gross leak test stage of the volumetric fill test will make sure there are no gross leaks in the part prior to conducting the fine decay leak test.

Without this approach, you could fill up the volume of a gross leaking part during the fill stage of the test and never be able to check for a small leak because there wouldn’t be an air pressure differential on the part chamber.

Choosing a Leak Test Method for IPXX Testing

There are three different methods typically used for IPXX texting. The selection will depend upon the specific part being tested. Part characteristics, leak paths, usage context, and risk of failure will always dictate actual required reject leak rates. The info below provides a basic overview—the leak rates indicated are only generalized industry estimates.

Talk to a leak test expert at CTS to find the right approach for your IPXX test.Pressure Decay

Use for open parts that will be sealed and pressurized internally with leak rate of 1-10 scc/m.

Differential Pressure Decay

Better for parts that require low leak rates, 0.5 – 5 scc/m.

Tracer Gas Sniff/Accumulation

Large parts with low leak rates. Also for parts that expand due to pressure or where testing repeatability is affected by variables. For leak rates of <7 scc/m.

Using Gross Air Leak Testing for IP67 Compliance

In this approach, the volumetric fill introduces a known reference volume into the test circuit and uses equalization of a known pressure to accurately measure the leak. If the part has a gross leak the test would not meet the ‘target pressure window’ specification and fail the gross leak test. If the passes the gross leak test the program automatically performs the fine pressure decay leak test.

The diagram shows an example of the sealed device leak testing process.

Get practical information on IPXX testing

Browse our IP67 resources for webinars, ebooks and how-tos to help you with your testing.

Understanding Reference Volume in Sealed Device Leak Testing

Imagine the volume of your reference air tank being the same of the volume of the free space of the chamber surrounding the outside of the part and neglect all the tubing and inefficiencies. If the reference volume, which is 5 psig in our example, is allowed to flow into the test chamber with a good part then the equalized pressure would be around 2.5 psig.

If there was a gross leak in the part and the part was the same volume as the reference tank, then the new pressure would be 01.25 psig and the test would fail. If the part passes the gross leak test a ‘fine’ pressure decay leak test is performed on the part.

Performing a Volumetric Fill leak test on ‘seal parts’ ensures your parts are leak-tight and conform to IP67 ingress contamination standards.

Have questions?