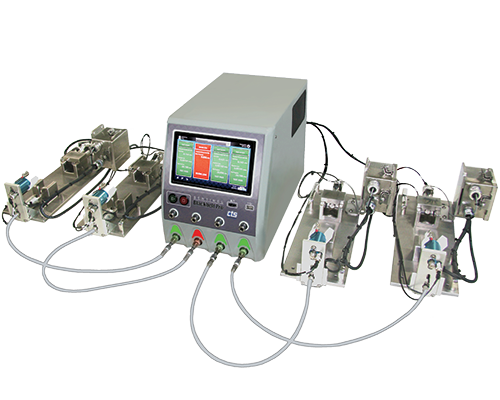

Sentinel Blackbelt Pro Multi-Channel Leak Test Instrument

The Sentinel Blackbelt Pro™ is an advanced multi-test, multi-port, multi-channel test instrument for leak, flow pressure and vacuum testing. One Blackbelt Pro instrument can manage and execute 4 individual part tests at different stations. It offers the flexibility of a custom instrument in a standard instrument platform.

Multi-Channel Blackbelt Pro Test Instrument Improves Productivity

Mass flow and pressure or vacuum decay leak testing methods are used during product manufacturing to assess leakage rates and verify the integrity of sealed parts. Trying to manage multiple tests, however, can slow production as you try to monitor and analyze data on separate leak testing systems.

The multi-channel Blackbelt Pro helps streamline manual and automated leak testing processes by providing up to 4 individual tests, synchronously or asynchronously, in one fully integrated unit. Conducting several tests with one system simplifies leak testing and reduces the space required.

Multi-port, Multi-test, Configurable for Leak, Flow, Pressure, and Vacuum Testing

The Blackbelt Pro performs the following test types:

- Pressure/Vacuum decay-pressure change

- Pressure/Vacuum decay-with certified leak standard

- Pressure/Vacuum decay-pressure change/time

- Occlusion test (vacuum or pressure test)

- Mass flow direct flow reading

- Mass flow with certified leak standard

Instrument highlights:

- Highly configurable and very flexible

- 4-port independent, synchronous and asynchronous test capability

- 1, 2, 3, or 4 port sequential operation

- Multi-test dependence programming

- Store up to 999 part programs

- 200,000 test sequencing

- Provide digital I/O control 18 inputs / 18 outputs with enhanced Tooling Control

- “SmartKey” digital ID tracking complies with 21 CFR Part 11

Benchtop and Wall Mount Multi-Channel Leak Test Instruments

Wall Mount Unit for Industrial Applications

The Blackbelt Pro Wall Mount is an industrial test instrument designed for leak, flow, pressure, and vacuum testing in automated or semi-automated processes. Its small footprint cabinet provides room for multi-channel hardware, wiring, and connections designed for easy installation and maintenance. The modular design of the wall mount instrument allows specialized configurations to be contained in an efficient footprint as the enclosure is expanded to include all the upgrades that can be integrated with the instrument controls.

Benchtop Unit for Medical Device Testing

The Benchtop unit is an advanced small package design integrated with controls and pneumatics to simultaneously. Commonly used by medical device manufacturers for manual or semi-automated tests, the Benchtop is supplied with the test port connections on the front of the unit for easy connection.

For examples of applications using the Blackbelt Pro, browse our application bulletins.

Blackbelt Pro Is 21 CFR Part 11 and EU Annex 11 Friendly

The Blackbelt Pro includes features that support both 21 CRF Part 11 and EU Annex 11 compliance:

- Unique user IDs

- Audit and activity log

- Instrument edit comments

- PDF report generation

Automate Leak Testing with a Turnkey Benchtop Solution Controlled by a Sentinel Blackbelt

Reduce operator effort and increase efficiency with an automated leak and flow benchtop test system for medical devices.

Documentation

Locked items require an account for access. Login or create an account. Login or create an account.

Brochures

Datasheets

User Manuals

One Blackbelt Pro instrument can replace 4 independent test instruments.

A Blackbelt Pro can control, manage and execute 4 part tests synchronously or asynchronously, at different stations. Contact Us to select the proper standard test instrument for your application.

Request A Quote

Please provide as much information below as possible to help us prepare an accurate quotation. Once done, click “Add to Request”. When ready, you can review, add notes, and submit your request through the cart icon on the upper right of the screen.

Sentinel Blackbelt Pro successfully added to quote request!

Click here to viewCTS will contact you to confirm test sequence and instrument configuration.

Contact CTS

To Discuss Your Leak Detection System Requirements

Contact CTS

Contact Cincinnati Test Systems to learn more about our leak detection equipment

Contact UsCustomer Login

An account is needed to view restricted documents such as user manuals and to submit RFQ requests.

Sign In