Cincinnati Test Systems (CTS) has the Single Station Wheel Rim Test System solutions you need. Our Single Station Wheel Rim Test System is engineered for superior performance and ease of use, and will deliver highly accurate test results in quick cycle times. These systems can be customized to the needs of a wide range of applications.

Cincinnati Test Systems designed and built this single station turnkey leak test system to test wheel rims for cracks and porosity.

Cincinnati Test Systems designed and built this single station turnkey leak test system to test wheel rims for cracks and porosity.

Cincinnati Test Systems designed and built this single station turnkey leak test system to test wheel rims for cracks and porosity.

Cincinnati Test Systems designed and built this single station turnkey leak test system to test wheel rims for cracks and porosity.

Single Station Wheel Rim Test System

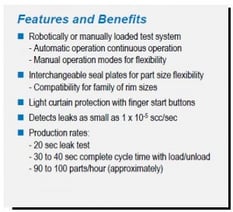

CTS designed and built this single-station leak test system to test wheel rims for cracks and porosity. The testing process incorporates both vacuum decay and helium mass spectrometry to determine gross leaks, medium leaks, fine leaks, and accepted parts. The system allows for manual and robotic loading and unloading. To test wheel rims, they are pressurized in the same manner as when they have tire air pressure applied to them. After parts are loaded, the system’s telescoping chamber moves down over the wheel rim, sealing the hub on the outside diameter. The chamber seal uses interchangeable seal plates to incorporate wheel rims from 13” to 20” in diameter, and from 4” to 10” in width. Once the seal is completed, the system pulls vacuum on both sides of the wheel rim. The pressure side is isolated and pressurized with 100% helium, while the hub remains under full vacuum. Gross leak testing is performed on the hub side vacuum source prior to the helium mass spec leak test. This multi-stage test process reduces test times when a large leak is detected in the rim. It can also reduce helium background cleanup, which can slow production testing when excessive helium is released into the mass spectrometer. After the gross leak test is passed, helium mass spectrometry is used to measure fine leaks within the wheel rim. Fine leak rates range from 5 x 10

-4 to 1 x 10

-5 scc/sec. Once this test is completed, helium is evacuated from the pressure side to a CTS helium reclaim system, and the entire system is opened to atmospheric pressure. The wheel is unclamped, and robotic mechanisms unload the tested wheel rim and loads the next. Total cycle time is approximately 20 seconds.

Once the seal is completed, the system pulls vacuum on both sides of the wheel rim. The pressure side is isolated and pressurized with 100% helium, while the hub remains under full vacuum. Gross leak testing is performed on the hub side vacuum source prior to the helium mass spec leak test. This multi-stage test process reduces test times when a large leak is detected in the rim. It can also reduce helium background cleanup, which can slow production testing when excessive helium is released into the mass spectrometer. After the gross leak test is passed, helium mass spectrometry is used to measure fine leaks within the wheel rim. Fine leak rates range from 5 x 10

-4 to 1 x 10

-5 scc/sec. Once this test is completed, helium is evacuated from the pressure side to a CTS helium reclaim system, and the entire system is opened to atmospheric pressure. The wheel is unclamped, and robotic mechanisms unload the tested wheel rim and loads the next. Total cycle time is approximately 20 seconds.