How to Leak and Blockage Test Microfluidic Chips

Market Requirement:

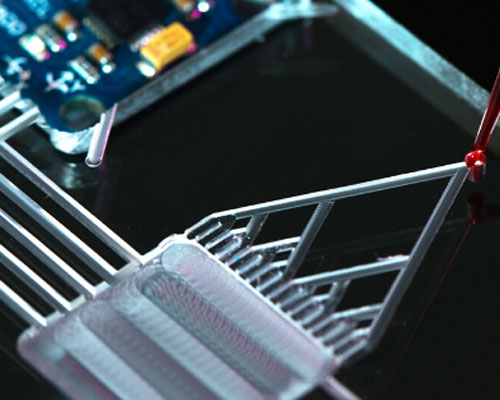

Microfluidic chips are used in a multitude of biological diagnostic applications, including analytical separation, detection, fluid control (sampling/mixing) and more. Once placed within durable analytical instrumentation, these devices typically have multiple unique micro pathways isolated from one another for liquid media passage, sampling and analysis.

Today, many mass-produced chips are manufactured using injection-molded polymer layers which are laminated, or bonded, together to form tiny sealed pathways for liquid media passage. These pathways are sometimes only a few microns wide and deep. As liquid flow control is paramount to the functionality of these devices, assembly failures due to either leakage or blockage must be detected in production.

Commonly used names for Microfluidic Disposable Devices:

- Lab-on-a-chip

- Microfluidic cartridge

- Microfluidic cassette

- PCR chip

- PCR cartridge

- PCR cassette

- Molecular diagnostic chip

- Molecular diagnostic cartridge

- Molecular diagnostic cassette

- Point-of-care chip

- Point-of-care cartridge

- Point-of-care cassette

CTS Solution:

Testing 100% of parts in production typically requires dry positive air or nitrogen pressure and/or vacuum leak testing with a single-channel (often multi-port sequential) Sentinel Blackbelt or multi-channel concurrent Blackbelt Pro instruments.

These devices commonly require a two-step process to detect both leaks and potential blockages on each unique microfluidic pathway within each chip.

Contact CTS

To Discuss Your Leak Detection System Requirements

Contact CTS

Contact Cincinnati Test Systems to learn more about our leak detection equipment

Contact UsCustomer Login

An account is needed to view restricted documents such as user manuals and to submit RFQ requests.

Sign In