How to Leak Test Non-Compliant Balloon Catheters

Market Requirements:

Non-compliant balloon catheters are equipped with an inflatable balloon near the distal or outlet of the device. Typically made of polyester/PET or nylon, they are capable of inflating to a specific diameter at relatively high saline or radiopaque solution injection pressures. They are often used for vessel dilation and/or stent delivery.

Common Non-Compliant Balloon Catheters:

- Angioplasty (PTA & PTCA) catheters

- Dilation (esophageal, sinus, gastric, venous, arterial, biliary) catheters

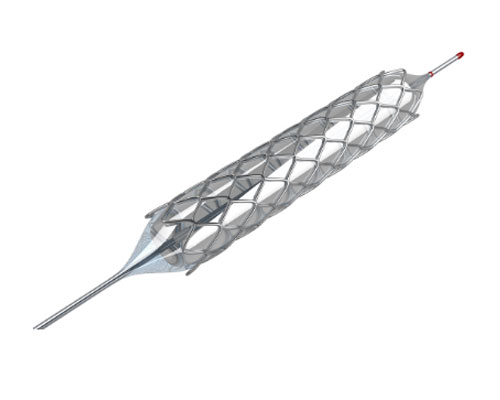

- Stent delivery catheters

- Heat transfer catheters

- Laser balloon catheters

- Cryogenic catheters

- Drug delivery catheters

- Atherectomy catheters

- Sinuplasty catheters

- Carpal tunnelplasty catheters

- Kyphoplasty catheters

CTS Solution:

For non-stented non-compliant balloon catheters, most applications require pressure decay testing using clean, dry nitrogen or compressed air at positive pressures ranging from 150 psig to 450 psig—in some rare cases up to 1000 psig. Standard single-channel Sentinel Blackbelt or multi-channel Blackbelt Pro pressure decay instrumentation can be used for these tests.

For stented non-compliant balloon catheters, most applications require using either vacuum or very low positive pressures between -12 psig to +10 psig to prevent deforming the stent during the test.

Contact CTS

To Discuss Your Leak Detection System Requirements

Contact CTS

Contact Cincinnati Test Systems to learn more about our leak detection equipment

Contact UsCustomer Login

An account is needed to view restricted documents such as user manuals and to submit RFQ requests.

Sign In