Ideal methods for IP67 device and sealed component leak testing

In our previous post, we discussed the use and parameters of IP67 (and IPxx) ratings. In this post, we will discuss ideal methods for IP67 device and sealed component leak testing.

The ideal approach for leak testing to the IP67 standard is to test with air, using a volumetric fill test with pressure. This is non-destructive, measurable and quicker to keep pace with production when compared to other methods, like dunk testing, for example.

Conventional pressure or vacuum decay testing methods, are not applicable here. That’s because the sealed device usually lacks any ports, valves, or other means of creating pressure inside of it in a controlled manner for testing purposes.

This calls for the use of a sealed chamber, custom fit to the device or part to be tested. To optimize both test cycle time and the sensitivity of the test, and ensure test repeatability and reliability, it’s best to have no more free air space around the test item within this sealed chamber than there is within the item itself—which can be quite small when it comes to leak testing consumer electronics, etc.

We then proceed with a volumetric fill test with pressure. We test first for any gross leaks (large holes) and then for the fine leak test that will determine pass/fail.

CTS’ two-step approach for sealed device leak testing to meet IP67 requirements

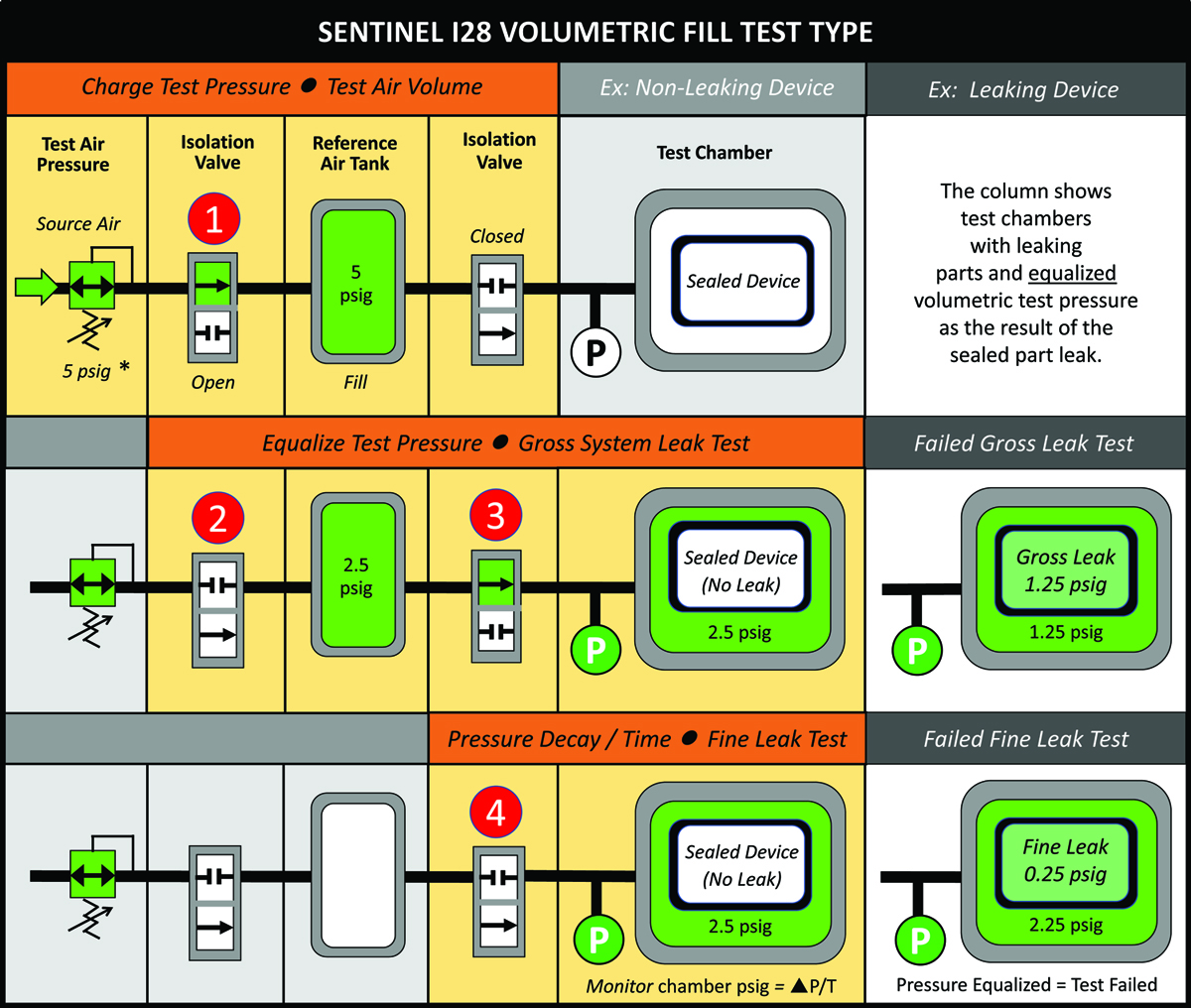

CTS uses a two-step approach for sealed device leak testing to avoid the issues that commonly lead to false “pass” results. For example, a sealed device with a gross leak will pass a fine leak test when tested without a controlled fill. This happens because test pressure will fill the chamber and part at the same time, which results in no pressure change being measured during the actual test.See the below diagram for a visual example of this:

Gross leak test

For the gross leak test, air travels into the test chamber via the chamber’s isolation valve, and pressure is equalized between the chamber and the reference volume tank. Gross leak testing provides almost immediate results by verifying that equalized pressure between the two volumes has not fallen below a pre-set pressure. If a sealed device passes the gross leak test, it can then undergo fine leak testing.Fine leak test

A fine leak test measures pressure loss in the test chamber over an extended period of time. The test chamber’s isolation valve is closed, and pressure inside the chamber is monitored for gradual loss. Any change in pressure indicates that air from the chamber is infiltrating the test item. The fine leak test measures either a pressure drop over time (x psi loss per x seconds) or a calibrated volumetric flow rate (scc/m – standard cubic centimeters per minute) which correlates to no water ingress for an IP67 rating.Other testing methods for IP67 leak testing

While the above testing process is often the most ideal method for IP67 leak testing, some situations may call for alternatives, as below.Vacuum Leak Testing

Instead of pressurizing the test chamber, it can be evacuated to create a vacuum. This will determine if air is leaking from the test item. The vacuum leak testing approach may be used in situations where the item in question is expected to undergo substantial atmospheric pressure changes during regular use.Helium Leak Testing

Another option is to bombard the test item with helium in lieu of pressurized air and then sniff for any evidence of leaking helium with a mass spectrometer. This method, however, is typically reserved for acceptable leak rates more stringent than IP67.

In the majority of cases, volumetric fill testing with pressure is the ideal way to ensure sealed devices and components are indeed achieving an IP67 rating as advertised. This test method delivers the reliability, repeatability and objectivity manufacturers need to maintain production volumes, reduce scrap and rework, and contain costs.

Learn more about CTS’s IP67 test capabilities by reading this case study.