We help you make them leak-free.

You build products to power our world.

Energy Industry Testing Systems & Equipment

Few areas of the economy have received more attention (and funding) than the energy sector. Advancements in geothermal, wind, natural gas, bio fuels, fuel cells, nuclear, and advanced battery technologies dominate the global landscape. CTS has led the wave of innovation by providing the energy sector with advanced technology and innovative test solutions. In fact, in 2008, we partnered with the United States Department of Energy to begin exploring test methods for high volume, fuel cell manufacturing.

Contact us to discuss available options for green energy leak detection systems.

Effective Solutions for Green Energy Leak Detection

Helium leak testing is popular because the tracer gas passes easily through leaks and is non-toxic and non-flammable. Testing using helium leak detection is more accurate than using other tracer gases and is conducted using systems containing a Mass Spectrometer Leak Detector. The methods used during a mass spectrometer helium leak test include pressure testing and vacuum testing.

Pressure testing utilizes sniffer and tracer gas testing methods. The sniffer method involves filling the test component with gas and using a probe to monitor or “sniff” the air surrounding the component to detect the presence of leaking gas. During vacuum testing, the component is evacuated either within the detector or in a separate system, depending on the part size. A spray probe is then used to administer helium to the surface to detect leaks.

Both testing methods are used throughout the energy industry and equipment can be tailored to meet different testing requirements.

Pressure Decay and Mass Flow Instruments for Turbine Leak Detection

Wind turbines are now common worldwide. Wind turbine leaks can cause mechanical issues that impact their performance and efficiency. Leaking hydraulics not only cause maintenance issues but can pose an environmental danger if the fluid leaks into soil or water supplies.

Pressure decay and leak detection equipment provided by CTS ensures that components for the wind turbines are leak free and are running within normal ranges of operating efficiency. Our turbine leak detection solutions include mass flow instruments that are multi-test configurable and feature auto calibration and storage for up to 99 pre-programmed test sequences.

Mass Spectrometer Helium Leak Tests for Alternative Fuel Delivery and Storage

As oil prices continue to rise and emission regulations become more stringent, the need for clean technologies continue to grow. As new gas alternatives become a more commercially attractive fuel for automobiles, CTS is poised to offer mass spectrometer helium leak tests or pressure/flow based solutions for delivery and storage systems.

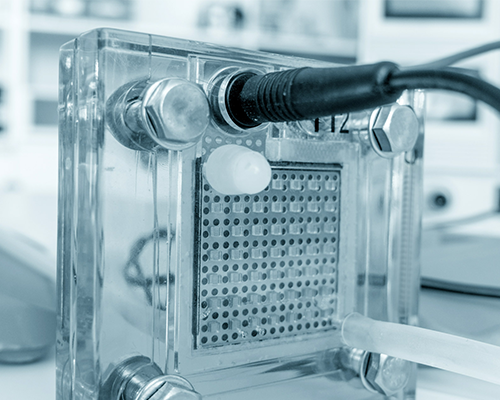

Battery Leak Testing of Hydrogen Fuel Cells

Hydrogen fuel cells use gas flow and diffusion to convert chemical energy into electrical energy. Leaks can occur in cell blocks, plates or electrodes but by testing these components prior to assembly, you can help prevent final product defects. From testing fuel cell plates and sub-assemblies to leak and functional testing of fully assembled fuel cells, CTS has proven to be an innovative and reliable partner.

CTS has demonstrated the propensity to offer innovative battery leak detection equipment and function test solutions that keep pace with the rapid advancements in the energy sector. Our battery leak testing solutions include differential mass flow and helium mass spectrometer detector systems for advanced battery technologies.

CTS has demonstrated the propensity to offer innovative battery leak detection equipment and function test solutions that keep pace with the rapid advancements in the energy sector. Our battery leak testing solutions include differential mass flow and helium mass spectrometer detector systems for advanced battery technologies.

Leak Testing in Manufacturing Green Energy Products

Contact Us to discuss your green energy leak detection requirements and learn more about how CTS can help with your specific test solution needs. We offer a wide variety of testing solutions for green energy leak detection and can work with you to create customized equipment for your unique needs.