Leak Testing Electronic Components in Electric Vehicles

Manufacturers of electrical components that must be water-tight can state the components water-tightness with an IP Code (Ingress Protection Code as defined by the International Electrotechnical Commission - IEC). This code identifies how well a component is protected from water or dust ingress. We have experts in this field who have been supporting many different industries with this challenge. Our experts work through discussions about the application and help coach customers in setting leak rates related to measurable leak testing for identified IP specifications.

Often the challenge is that IP code descriptions are attribute tests identifying the physical properties of water and dust ingress, while production leak testing uses the measured flow of air media correlated to “no flow” of water or dust into a component.

The CTS team can help you through these challenges while discussing leak testing solutions that can meet your leak testing needs. Our team’s expertise includes early discussions about measurable specifications as non-water leak rates, pre-order laboratory testing support, supplying instruments and turnkey testing systems for repeatable testing measurements. These instruments or systems will be engineered specifically for your application whether it is in a laboratory, prototype, or production environment.

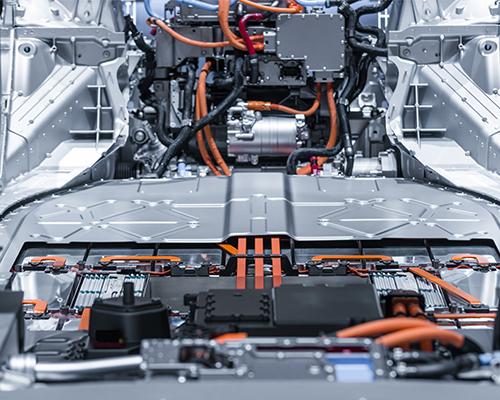

Leak Testing for Water-tight EV Assemblies

Learn how to choose the right technologies and methods for leak testing water-tight EV assemblies such as batteries, drive units, charge station components and more.

Guides and Other Resources on Leak Testing Sealed Electronics

If you want to leak test to an IP-rated specification, we have many materials to help you understand the challenge and optimize your test!