Leak Testing Large Volume Parts in Manufacturing

Leak testing of large volume parts such as EV battery packs poses unique challenges on the production line. The larger the internal volume of the part, the more air must be pumped into the part to test it. Increased air volume makes it more likely that the test will suffer from pressure and temperature shifts that will skew the repeatability of the test results. CTS test systems are able to compensate for these factors to provide a reliable leak test.

Variables in Leak Testing Big Parts

The key challenge is the “thermal effect” – the more air that is compressed into a cavity, the more its temperature increases. The larger the cavity and the greater the air volume, the greater the volatility of this temperature shift. Test cycles may have to be extended to achieve thermal stabilization for a reliable test result.

The unpredictably of these variables – test pressure, volume, and temperature – on the measured leak rate is further compounded by:

- The test part’s internal volume and geometry

- Its materials

- The test pressure being used

- How the part’s temperature when it arrives at the test station may be in flux due to a previous production step such as a wash or exposure to cold air

- The environment in which the part is being tested

The only way to fully identify and compensate for these variables is to employ more effective measurement using data-driven analytics.

Reliable Leak Test Equipment for Large Assemblies

Two common methods for large-volume leak testing are pressure decay with compensation factors and mass flow with specialized pressure control. CTS has two instruments optimized to address the unique challenges of large volume leak testing: the new Sentinel I28 EV and the Sentinel 3520.

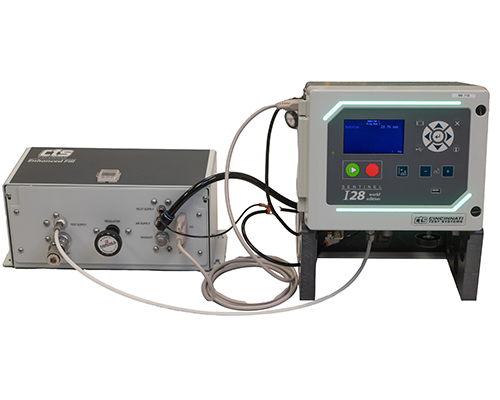

Sentinel I28 EV

Cincinnati Test Systems has integrated proven measurement solutions into the Sentinel I28 pressure decay leak test instrument to address the variables associated with testing large volume parts. Because the Sentinel I 28 instrument platform is integrated with many standard features that assist customers in simplifying their testing processes it allows a level of simplicity for integrating solutions that solve large part testing problems with:

- Quick Fill Pressurization

- Target Pressure Correction

- Ambient Pressure Correction

- Characterized Batch Calibration

- Absolute pressure control that maintains a constant pressure during test

- Multi-stage pressure control that achieves precision leak detection in high volume parts and optimizes fill time

- Absolute pressure regulation that mitigates atmospheric pressure changes

- Temperature compensation that mitigates environmental changes

- Automatic calibration that ensures accurate assessment of the leak rate

All this enables operators and quality engineers to compensate, in production real-time, for the variables that can skew the measured leak rate in a large volume leak test.

Talk to a Leak Test Expert about Your Large Volume Leak Test

CTS is a world-wide leader in leak test technology. Contact us to learn more about the best option for your needs.